Tesla News

- ~에 의해 Lars EVBASE

BP Partners with Tesla in a $100 Million Investment to Boost EV Charging Infrastructure

- ~에 의해 Lars EVBASE

Toyota's Late Leap into the EV Race: A Misstep or Calculated Delay?

- ~에 의해 Lars EVBASE

Misleading Maneuvers: The Tumultuous Road of BMW in the Electric Vehicle Arena

- ~에 의해 Lars EVBASE

Tesla’s Strategic Price Cuts: Paving the Road to Sustainable Energy

- ~에 의해 Lars EVBASE

Union Strikes and Electric Dreams: A Rocky Road Ahead for the Big Three

- ~에 의해 Lars EVBASE

Ford's Electric Strides in Q3 Overshadowed by Tesla and Rivian’s Pace

- ~에 의해 Lars EVBASE

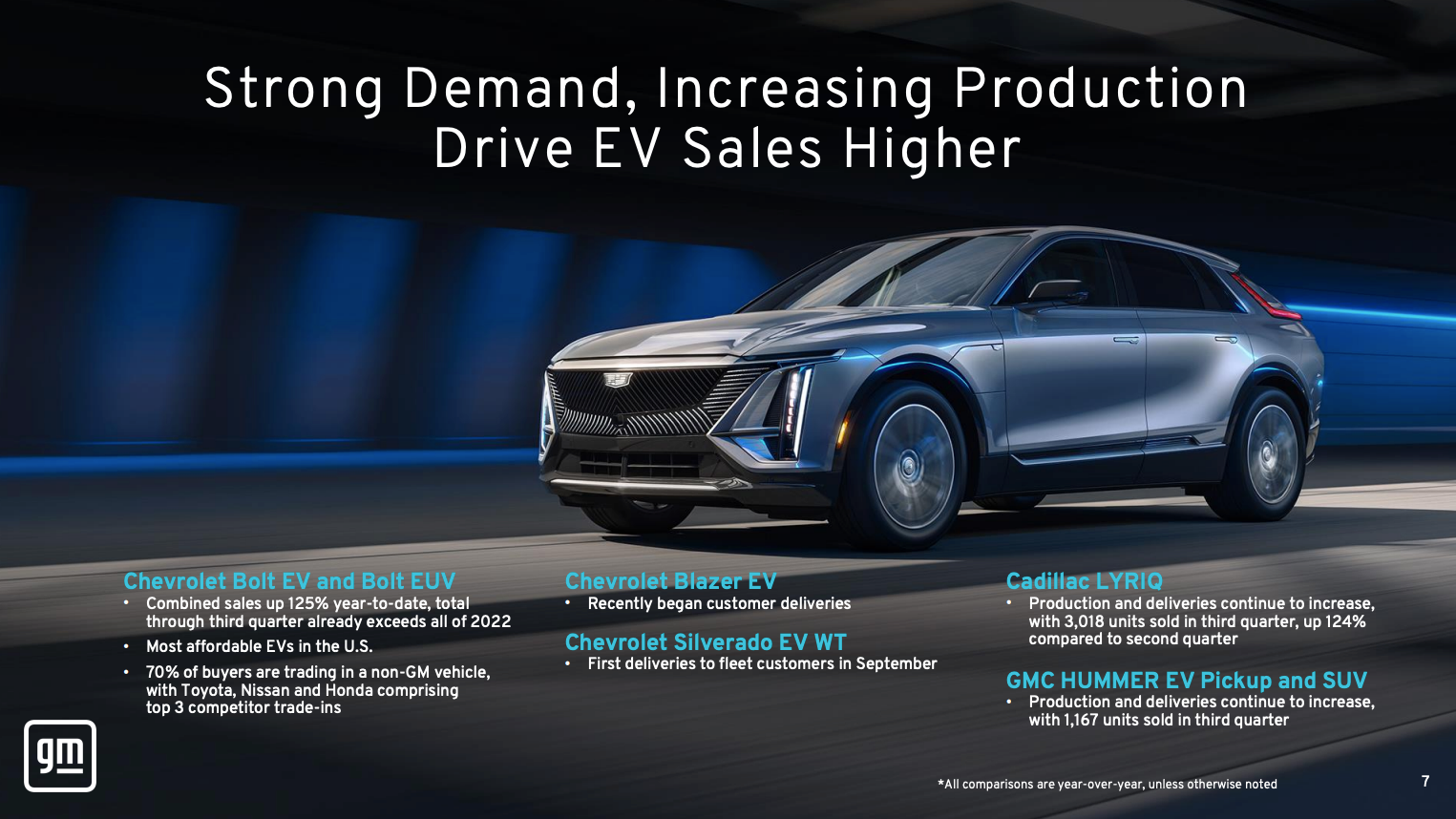

GM's Modest Electric Vehicle Progress in Q3 2023

- ~에 의해 Lars EVBASE

Tesla's Q3 Performance and the Bigger Picture

- ~에 의해 Lars EVBASE

The Saga of Unfulfilled Promises: Volkswagen's Rough Road Amid EV Aspirations